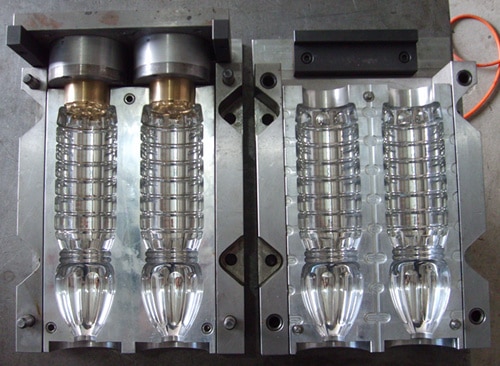

We always focus on "quality, innovation, service" on competition in the international market environment, we have succeeded in from Germany, Italy, the introduction of the latest beverage packaging technology.įirst-class manufacturing equipment supplier Mainly engaged in the whole production line of soft drinks and food, the main products are: PET Preform cap injection molding, blowing machine 2000-36000 bottles per hour of water / juice / carbonated beverage production line cans filling production line 3/5 gallon drums water production line various liquid filling lines. The preform is injection moulded as a separate stage, in a. 9, isolated air control system, prevention of pollution from exhaust emissions workshop. The two-stage blow moulding process is used for standard and stretch blow moulded items (Fig. 8, sealing and tensile design of cylinder body, left and right cylinders into a group, do not interfere. Water Bottle,Juice Bottle,Carbonated Drink Bottle.etcġ, the use of double-crank diagonal arrangement, four-lever clamping, clamping speed, strong clamping force, clamping joints tight and thin.Ģ, the use of chain adjustment system is simple and fast.ģ, the only use of integral casting rack, weight, not easy to shake.Ĥ, the use of rigid rail before removing the template, in the template structure, 100% not preform production, greatly enhancing the safety, reliability and stability of the machine.ĥ, dual boot working and safety devices to prevent work-related injuries.Ħ, advanced power generation systems designs,ħ, gas is advanced in design, with buffer, all moving parts work smoothly, shock, low noise.

0 kommentar(er)

0 kommentar(er)